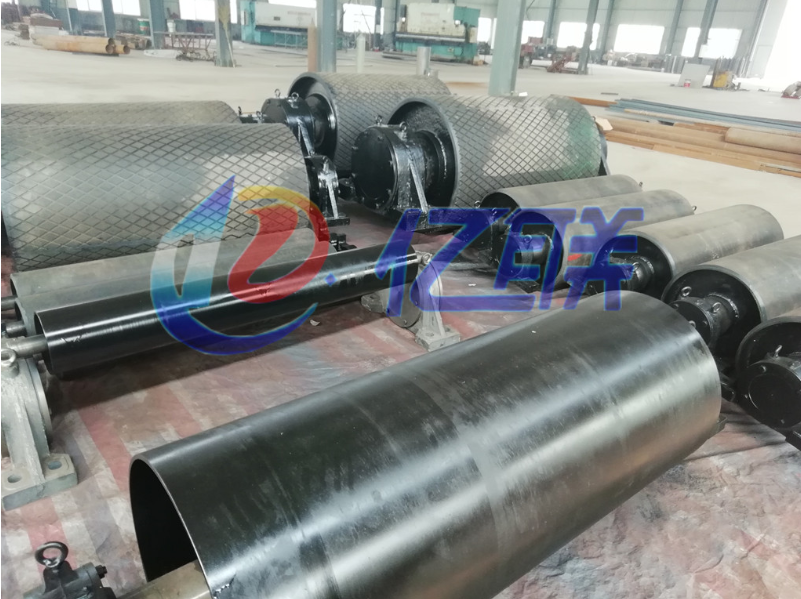

滾(gun)筒(tong)是(shi)傳遞動力(li)的主要(yao)部件(jian),皮帶機包膠(jiao)滾(gun)筒(tong)一般輸送(song)塊(kuai)狀物料的混(hun)合(he)物(礦石、煤(mei)),設備連續(xu)作業時(shi)間長,這要(yao)求滾(gun)筒(tong)具有較高的耐磨性、*高抗(kang)拉力(li)及(ji)抗(kang)撕裂性能。如果是(shi)露天作業,滾(gun)筒(tong)還易(yi)受天氣(qi)影響(如生銹、污泥(ni))。而傳統橡膠(jiao)滾(gun)筒(tong)易(yi)磨損、打(da)滑(hua)跑邊、損壞輸送(song)皮帶,造(zao)成皮帶機輸送(song)負(fu)荷下降(jiang),設備更換頻繁。

膠(jiao)帶運(yun)輸(shu)機(ji)在滾(gun)筒(tong)(tong)(tong)驅動(dong)(dong)的(de)情況下,需要增(zeng)大機(ji)械傳動(dong)(dong)輸(shu)送與(yu)筒(tong)(tong)(tong)體表面的(de)摩(mo)擦力,以(yi)減少輸(shu)送帶在滾(gun)筒(tong)(tong)(tong)表面滑移時相互(hu)磨(mo)(mo)損,提供穩定的(de)運(yun)行牽(qian)引(yin)力,并延長膠(jiao)帶和滾(gun)筒(tong)(tong)(tong)的(de)使用壽命。我公司研發的(de)耐磨(mo)(mo)陶瓷(ci)包膠(jiao)傳動(dong)(dong)滾(gun)筒(tong)(tong)(tong)是以(yi)表面有(you)暗格剛玉陶瓷(ci)為抗磨(mo)(mo)損層,以(yi)增(zeng)加其(qi)表面摩(mo)擦力,以(yi)具有(you)耐磨(mo)(mo)橡膠(jiao)著稱(cheng)的(de)聚(ju)氨基甲酸(suan)乙酯為硫(liu)化層,再(zai)用進(jin)口(kou)高(gao)強度(du)膠(jiao)粘(zhan)劑粘(zhan)接(jie)而成。正常使用壽命是橡膠(jiao)包膠(jiao)滾(gun)筒(tong)(tong)(tong)的(de)10倍(bei)以(yi)上

- 上一篇:聚氨酯陶瓷片棒條篩板

- 下一篇:箱式稀油激振器